The following History of the Fender Custom Shop is courtesy of Guitar.com and is reused with permission.

The History of the Fender Custom Shop

Often the term ‘custom guitar’ implies something special-order, made with unusual features and non-standard specs. For Fender players of the past 30 years, however, the term more likely denotes an effort to recreate the best of the company’s guitars of the 50s and 60s. In reality, the Fender Custom Shop was founded to do both.

Most guitarists, and Fender fans in particular, know the basic history of the Custom Shop, which celebrates its 30th Anniversary this year. In the midst of saving Fender Musical Instruments Corporation (FMIC) from ruin and recapturing the strengths of this once-mighty guitar brand, Bill Schultz also decided to establish a ‘best-of-the-best’ department, where top-level luthiers would craft the finest renditions of both traditional Fender models and adventurous new designs, to suit the needs of name artists and special-order clients alike. But how did the climate at a newly reformed company foster this effort, and how did the venture really come together?

We asked Fender Custom Shop co-founders Michael Stevens and John Page to talk us through it, but first let’s go back a few years.

With the implosion of Fender Musical Instruments looking imminent at the end of CBS’s reign, existing CEO Bull Schultz and a group of investors – including Dan Smith from the CBS-era management team – swooped in 1984 to purchase the rights to the Fender name and designs. Having reconfigured the operation as FMIC, the new owners initially set about pulling the basic models from the ashes and establishing a new factory in Corona, California – the Fullerton plant not having been included in the terms of the sale. Once FMIC had its feet on the ground, though, Schultz wanted to remind the guitar world how good a Fender could be. To do this, he needed a Custom Shop, and he tasked FMIC Vice President Dan Smith with setting it up. To understand how he did so, however, it’s worth briefly considering the backgrounds of the individual members of the two-man team he called upon.

Michael Stevens: From ranch hand to electric guitar royalty

Stevens had begun his career in earnest in 1967, working with the late Larry Jameson at the famed Guitar Resurrection in San Francisco, California – a place where countless major Bay Area guitarists came for their repair and custom work. He later returned to his native Texas, and took a detour to pursue his other passion: training Arabian show horses at a ranch in remote McKinney, Texas. Returning to the guitar fold in 1978, Stevens opened his own workshop in Austin, where he repaired – and eventually built – guitars for another wave of major artists. Over the next few years, Stevens counted Stevie Ray and Jimmie Vaughan, Otis Rush, Albert King, Eric Johnson, Lonnie Mack, Hubert Sumlin, Junior Brown and a whole slew of guitar legends among his clientele. But it was Stevens’s wild custom orders and original designs that really gained the attention of the wider guitar world.

“Fast-forward to the 80s,” Stevens tells us, “And I’d built the famous double-neck for Christopher Cross, the Git-Steel for Junior Brown, my Classic design, the Paul Glasse Model electric mandolin, and the Roscoe Beck six-string bass – most notably used on the bass solo on Robben Ford’s Talk to Your Daughter. So, I was at NAMM [in 1985] with Shadow because I was using their piezo saddles on my basses, and Robben was very tight with Dan Smith from Fender, so Roscoe brought him by the Shadow booth to meet me and see another bass I had there.” By this time, Stevens’ work had also been featured in several articles in prominent Japanese guitar magazines – where the push toward what we now call the ‘boutique’ guitar market seemed to be championed most vociferously – and he had also carved out a reputation as one of the most respected repair men in the vintage community. But this fame meant that Fender wasn’t the only one aware of Stevens’ abilities.

“It was in early 1986, after that NAMM show, that Dan [Smith] called about using me as a consultant, and again about licensing my design, and then about the Custom Shop concept – and finally about all three at once. Meanwhile, a Flying V I’d built won ‘Best of Show’ at the Dallas Guitar Show in 1986, and I got a call from Gibson about their Custom Shop, then run by Tim Shaw, an old friend. But I took the Fender job.”

John Page: From model maker to master builder

Unlike Michael Stevens, John Page had already had the bulk of his guitar-making experience at Fender by the time the Custom Shop was a glimmer in Schultz’s eye. “I initially started working at Fender in 1978,” Page relates, “And spent close to nine years in Guitar R&D – three as a model maker and six as a guitar design engineer with Freddie Tavares [hired by Leo Fender in the early 50s and co-designer of the Stratocaster]. I had left Fender at the end of January of 1986 to spend the year in the studio working on my music, but I did some design consulting for Fender as well.

“By around November of that year, I realised that I was going to have to go back to work somewhere, so I contacted Dan Smith and asked him if there were any openings. After talking with Bill [Schultz], Dan gave me the choice of going back into Guitar R&D, the position I had left in January, or working with Michael Stevens in the Custom Shop. Although we had discussed opening the Custom Shop many years prior, Bill had finally decided to make it happen. I thought that would be pretty cool, so I chose the latter.

“Dan told me they had met Michael – through Roscoe Beck, as I recall – and that he was going to be hired to start the shop, and I could work with him if I wanted. I think they had given Michael the chance to ‘yay or nay’ me, and fortunately we got along great, thus the partnership began.”

Setting up shop

Stevens recalls that, as a mover and shaker in the vintage-guitar world of the time, he hadn’t paid much attention to CBS-owned Fender and therefore didn’t know who John Page was. “I was told I could have an assistant of my choice, but would I speak to a few guys they thought would be good? I agreed,” he relates. “Page and I hit it off quickly, and I realised I needed his knowledge of Fender. Done!”

It seems Fender wanted to show off some Custom Shop product quickly, as in the upcoming ’87 Winter NAMM show that was just two months away, so before the official premises was even established in California, the Texan got down to it:

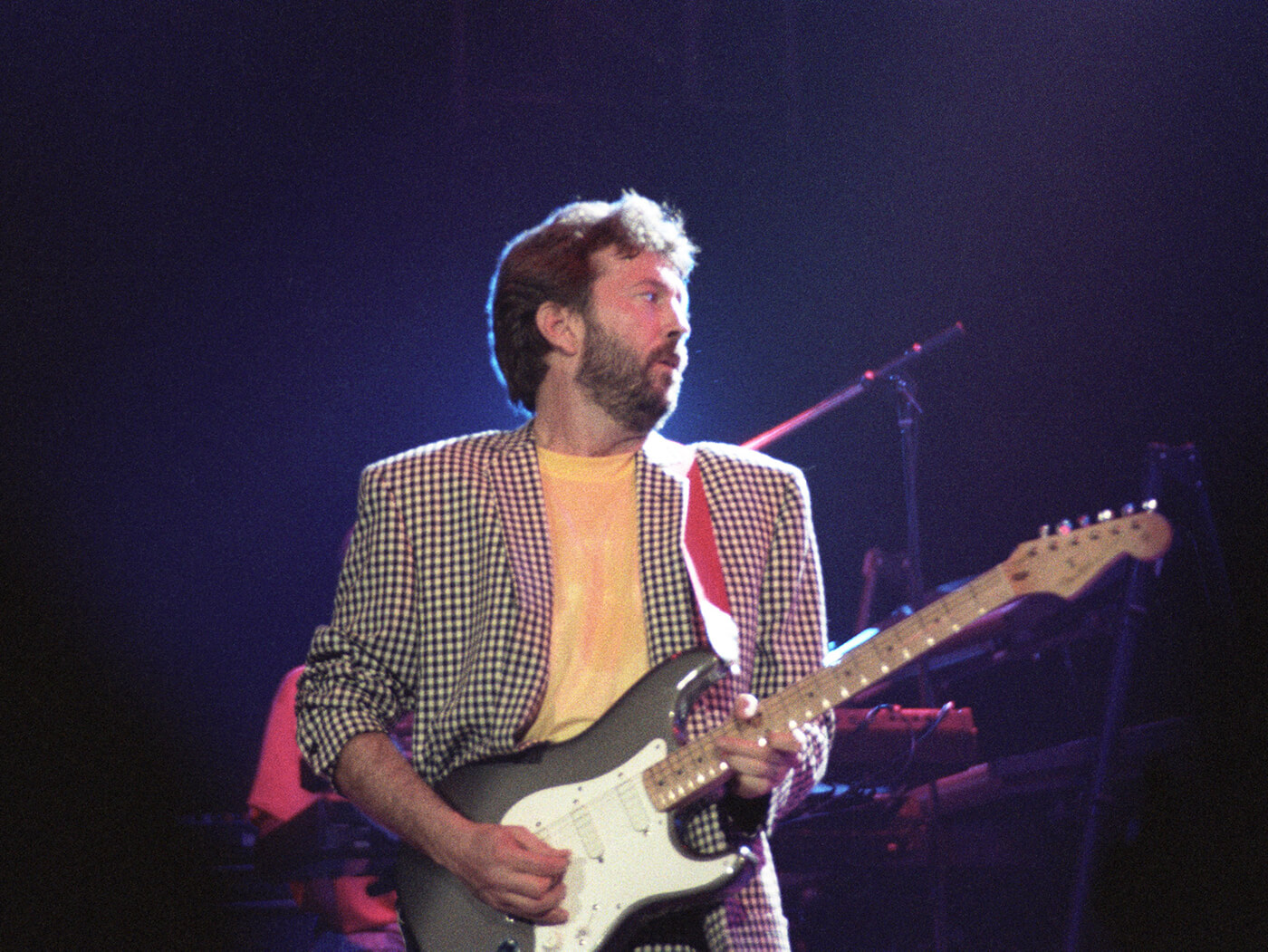

“In December of ’86 I went to work in Austin getting Eric Johnson two American Standards ready for NAMM, since he was already a customer of mine. They furnished lots of parts, necks and bodies to choose from, refret, tweak… When I got out there for NAMM, Alice [Stevens’s late wife] went off to find a house and I went to work in a very cluttered R&D shop in Brea to start getting necks ready for the Eric Clapton model that was hopefully soon to happen.”

For his part, Page confirms that the team was expected to hit the ground running, and initially to function in pretty scrappy circumstances:

“When Michael and I first started working in January of ’87, we were in the R&D Model Shop in Brea, a small, fenced off area in the warehouse, just outside of the R&D offices. Fender needed us to build some guitars, and our ‘real’ shop was yet to be built at the Corona factory. We only worked in there for a couple of weeks, as I recall, because then Michael had to leave to make the final move from Texas.

“While he was gone, I worked with the Corona Factory Manager to get the construction going on our new shop, an 800-square-foot area walled off from the main factory floor. I also started buying tools that we would need for the shop. Michael was used to tools that were mostly suited for smaller shops, like hand routers and such, while I was used to factory type tools, like pin routers. So we had both. When he returned about a month or so later, we ended up working in his garage shop for a couple of months. I think we complemented each other’s knowledge and skills, so each of us learned from the other.”

Page adds: “I remember a cool story: We didn’t have any air conditioning or heating in that shop, because that stuff was pretty expensive, so it got axed from my budget request. One summer’s day Bill Schultz came through with some of the members of the Board of Directors. I was hand-rasping the contours on a Strat body – I think it was an Yngwie prototype. I had a head-band on, sweating like crazy because of the heat. Bill saw it and I think he was a bit embarrassed by the working conditions that the board was seeing. He said, ‘Page, you need to get some air conditioning in here, you’re drenched!’ Boom, instantly approved! I wrote the purchase order that week… perfect timing!”

While Fender management might first have viewed the Custom Shop as a small showcase – a ‘jewel in the crown’ of the operation – that attitude quickly changed once the department’s potential became clear. Initially, says Page, Schultz saw the venture as “a couple of guys in the back 40 whittling away at some cool guitars. I don’t think he ever saw it growing to the extent that we ultimately did. He wanted us to be able to build anything that people wanted, and I think he saw us as being able to lift the overall quality image of Fender. Initially, he said he didn’t care if we made any money, he’d be happy if that broke even.” Soon, however – about six months into the operation, Page recalls – the image of the ‘jewel’ turned to dollar signs, and Fender insisted the Custom Shop become a profitable operation. Fortunately, it was already showing the potential to become bigger than anyone had anticipated.

“I went blasting into the Fender Brea office one morning,” Stevens recalls, “Greeted the new girl behind the desk, and was about the head on into the building when she stopped me. ‘Sir, do you have an appointment?’ I gave her my name, and she said, ‘Oh, you get more phone calls than everyone else in the office combined!’ The world was chomping at the bit.”

Rock star clients and staying power

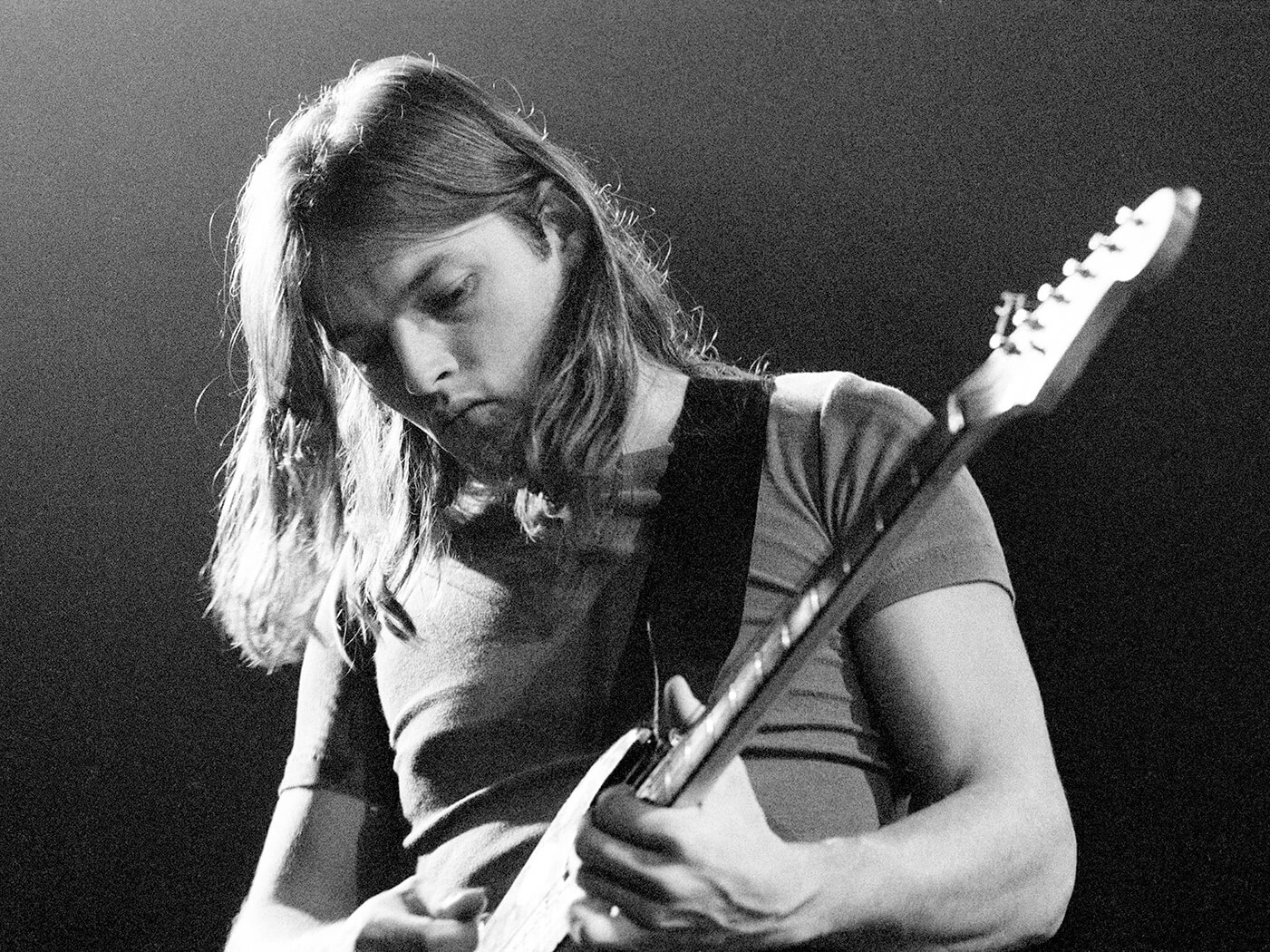

After the early guitars for Johnson and Clapton, Stevens and Page set about crafting guitars for what seemed a perpetually stellar list of big-name artists. Custom builds for Pete Townshend and David Gilmour were completed in the early days, and soon Yngwie Malmsteen, Elliot Easton, Caesar Rosas, Danny Gatton, Robert Cray, Waylon Jennings and a host of others joined the list. And that was just the beginning of the Custom Shop’s rock star associations.

Meanwhile, in late ’88 and early ’89 the Custom Shop also generated Fender’s first American set-neck solidbody guitar, the Stevens-designed LJ (named in honour of Michael’s friend from Guitar Resurrection, the late Larry Jameson). A clear bid to attack Gibson where they lived, this dual-humbucker model had a mahogany body with a maple top which Stevens carved in his own garage for lack of appropriate tooling at Fender. It even bore the ‘Stevens’ name on the front of the headstock, with the Fender Custom Shop logo on the back. Only around 30 Custom Shop LJs were ever built, although two renditions were also subsequently manufactured in Japan, and Stevens continues to build his own LJs to custom-order to this day.

In short, the Custom Shop not only turned the desired profit: it thrived. A decade after its inception it had grown into its own 30,000-square-foot premises filled with 60 employees – a roster that including notable Master Builders such as Fred Stuart, JW Black, John English, John Suhr, Stephen Stern, Gene Baker, Mark Kendrick, George Blanda and Alan Hamel, among others. But such rapid growth had already sent Stevens back to his beloved Texas where he created an independent one-man custom shop of his own in 1990. By the middle of that decade, Page was tiring of it too. He held on until 1998, when he left his position as head of the Custom Shop to become Executive Director of the Fender Museum of Music and the Arts Foundation. The Custom Shop’s founding twosome were gone, but not before they had carved out a substantial new chunk of Fender history.

“I guess around 1989,” says Page, “it really hit me that we had the opportunity to create this new piece of Fender history. By this time we had added a bunch of new employees. I used to have shop meetings, with all the builders and apprentices, and I remember saying that we were like the marines – we had to be the best, we were in new territory, and we could be gone tomorrow if we didn’t prove ourselves, not just by our artistry, but also financially. I think those were the days that it finally occurred to me that we were indeed writing a new chapter in Fender’s history. That’s also about the same time that my mentor, Freddie Tavares, came by to visit and told me that the shop reminded him of when he first started working for Leo Fender in the 1950s. That was monumental to me!”

For his part, Stevens also looks back fondly at what he helped to achieve for what was then a relatively young and much smaller Fender operation. “I’m particularly proud just to have gotten it jump started and headed with pride in the right direction,” he tells us. “Bill Schultz told me, ‘If we can only break even, I want the coolest Custom Shop on the planet!’ We did that, and put Fender back on the map.”

Mike Eldred took the helm of the Custom Shop upon Page’s departure in 1998, the launch of a long and successful tenure that lasted until his own departure in 2015, when Mike Lewis stepped into the job. Having begun as Fender’s ‘best of the best,’ the Custom Shop has continued to live up to that reputation, while fulfilling the needs of a far larger number of customers than Stevens and Page likely could ever have imagined at the start of it all back in 1987.

Michael Stevens continues to build guitars to custom-order in his workshop in Alpine, Texas, while also spending as much time on horseback out in the backcountry as he can possibly manage. John Page moved to southern Oregon in 2003, where he spent some time designing and building functional art furniture, before returning to the craft of guitar making in more recent years.

GUITAR.COM — 30TH SEPTEMBER 2019